Tyacht cooling tower serves Sichuan Gaojing, boosting the development of the photovoltaic industry

2024-08-20 13:09

Sichuan Gogreen Solar Technology Co., Ltd. (hereinafter referred to as "Sichuan Gogreen") is a subsidiary of Gogreen Solar Co., Ltd., established on July 22, 2022. The company takes "Let solar energy bring greater welfare to mankind" as its mission, and continues to focus on product quality and product value, driving the aggregation of the entire photovoltaic new energy industry chain, forming a new energy industry cluster, and helping China's green economic development. Contribute to the change of the global energy structure.

Sichuan Gogreen's first phase expansion project with an annual output of 13GW monocrystalline silicon rods will produce 25,997 tons of 182mm monocrystalline silicon square rods annually. Relying on the storage center, hydrogen production plant, argon production plant, power station, filter press workshop, and wastewater treatment station built in the first phase, the single crystal and machining workshop was expanded on the existing open space on the south side of the plant, with an expanded building area of 71,842.5 square meters; new single crystal furnaces, square cutting machines, 10kV transformers, cutters, square cutting machines, and CNC grinders were purchased and installed. Relying on the production and public auxiliary equipment such as the first phase chiller, air compressor, pure water equipment, nitrogen production equipment, argon recovery system (including hydrogen production), etc.

The equipment for producing monomer silicon in the single crystal workshop has a complex internal structure and has strict requirements on the furnace body temperature. If the furnace body temperature is too high, the furnace body will be deformed, affecting the accuracy of the equipment size, and thus affecting the product quality. In order to maintain the normal operation of the single crystal furnace equipment, prevent the equipment from being deformed due to excessive temperature and affect the growth of silicon crystals, a professional and stable cooling water system is required to provide circulating water with stable temperature and clean water quality to meet the cooling needs of the single crystal furnace, while eliminating equipment scale, reducing maintenance costs, and improving production efficiency.

Tyacht Cooling Tower supplied 42 TMC induced draft mixed flow closed cooling towers for this project . The tower flow rate is 550m³/h . The tower type has passed CTI certification and has high heat exchange efficiency, low energy consumption, low noise, long life, less drift water, no pollution, reasonable structure, reliable quality, stable performance, and easy operation and maintenance.

The tower body is made of aluminum-zinc plate with a thickness greater than 2.0mm. The main load-bearing structural parts of the closed cooling tower are made of hot-dip galvanized steel, which has good anti-corrosion and corrosion resistance. The cooling coil is made of 304 one-time formed stainless steel coil with a stainless steel pipe thickness of ≥1nm and a long service life.

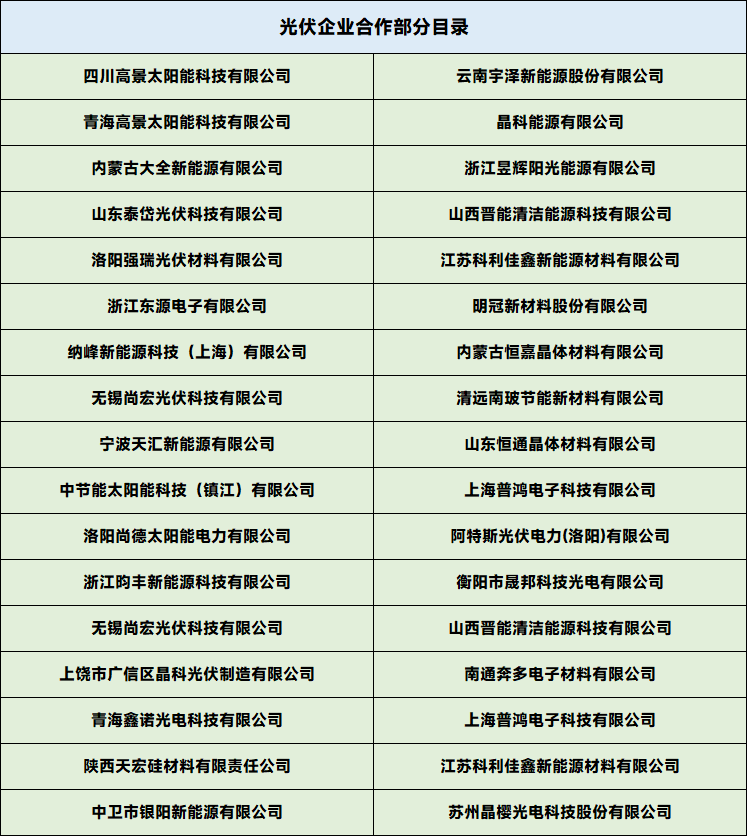

Earlier, Tyacht Cooling Tower had supplied 106 TMC induced draft mixed flow closed cooling towers for Sichuan Gaojing's annual production of 50GW monocrystalline silicon rods and 30GW monocrystalline silicon wafers . It was the excellent product technology and high-quality cooling tower products of Tyacht Cooling Tower that once again won the recognition of Sichuan Gaojing and reached another in-depth cooperation.

Sichuan Gogreen Solar's annual production of 50GW monocrystalline silicon rods and 30GW monocrystalline silicon wafers

The photovoltaic industry has high standards and strict requirements. Tyacht not only meets customers' stringent requirements for product performance and stability, but also becomes a close partner of customers with its professionalism and innovative technology. This is the market's affirmation of Tyacht cooling towers, and it is also a comprehensive recognition of its technical strength and service capabilities.

In the context of energy structure transformation, the importance of the photovoltaic industry is self-evident. In the future, Tyacht Cooling Tower will continue to uphold professionalism, continue to research product technology, and provide more stable and energy-saving products for the development of the photovoltaic industry.

Tyacht Cooling Tower will also continue to be customer-centric, market-oriented, and technology-driven, providing strong support for the comprehensive development of the photovoltaic industry, and at the same time contribute to the realization of the country's "dual carbon" goals.